Using technology to create a legacy for the next generation

It all started in 2007. John Moes and his son, Bryan, built their first monoslope barn, launching their cattle feeding business.

The goal was to diversify and give Bryan the opportunity to make a living on the family farm after college. In 2011, John expanded their facilities to hold 1,999 head of cattle.

Accelerating growth and improvement

When Bryan returned to the farm in 2014, he applied his college education and work experience to improve the family’s South Dakota operation. After his return, the Moes’ had even more success on the cattle they backgrounded, started finishing their own cattle and expanded into custom feeding.

The Moes’ partnered with South Dakota State University to conduct breeding research on their 350-head Angus cow herd. And in 2018, the Moes’ received the Environmental Stewardship Award for sustainably managing their farm’s shallow wetland habitat.

The Moes family has a history of being early adopters and striving to do things better. So when they heard about Performance Beef from their neighbors in 2017, they gave it a try.

“Getting our information away from a stack of papers and into Performance Beef has been really valuable to our operation,” John says. “Before, we were just adding up and hoping for the best.”

A technology transformation

Before using Performance Beef, they tracked everything on batch sheets and an Excel spreadsheet.

“Now, it’s all digital,” Bryan says. “It saves mental energy to let us do more of the higher-level thinking, like what are our metrics? Are we being efficient with our feed? Are our delivery times working?”

They’re always chasing better numbers, so Performance Beef’s ability to monitor every pound and every dollar by group is valuable.

“If we aren’t watching all those numbers, we aren’t going to be profitable and stay in business,” Bryan says. “Input prices are going up, so you have to produce cattle that will perform to stay in business.”

Managing down to the individual animal level

Bryan knows the power of data. But collecting that data effectively was a struggle.

“Once you spent two hours working cattle, you used to spend two hours at the computer, typing it all in. And I hate typing in numbers,” Bryan says. “This data is so valuable to us, but not if it’s taking all my time away from the management side.”

Moes Feedlot started using the Performance Beef animal health features to track individual animal performance and health. Bryan sees that as the future of their operation.

“We used to work these cattle and it wasn’t until hours or days later that we’d see, whoa, this calf only gained 1.1 pounds per day. Now, it’s right there right away,” he says.

.png?width=350&height=350&name=Instagram%20Resize_Bryan%20Moes%20(1).png)

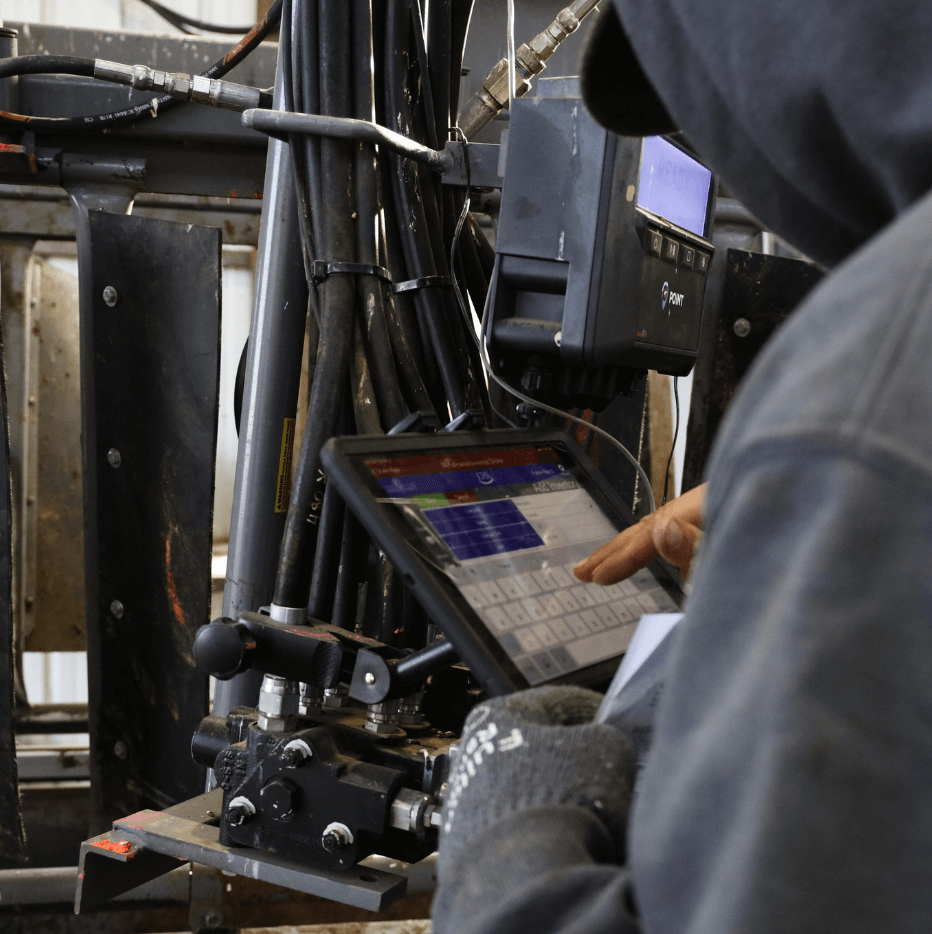

Using EID tags has helped to streamline data into the cattle software system.

“This technology gives us the ability to do stuff faster, more efficiently, more effectively and more concisely,” says Bryan.

Real-time data collected as the Moes’ run cattle through the chute fuels data-driven decisions. They can pick out poorer doers to separate so they can feed them to meet their needs, making their customers happy and, ultimately, boosting their bottom line.

Leaving a legacy

All the hard work John and Bryan have invested to build their operation is creating a legacy for the next generation. Bryan has five boys who all have a passion for the cattle. He wants to keep them excited and ensure they have ways to be involved in the future.

To succeed, John and Bryan believe you also have to work smarter and take advantage of every possible tool and technological advancement.

“We need to use technology to make our lives easier. Both so we could get more done, but also so we can be more effective at the end of the day and still have some family time,” Bryan concludes. “If we don’t start using it, we’re gonna lose it.”

READ MORE STORIES LIKE THIS

Proactive Care, Proven Results with Technology

Seven producer perspectives on managing cattle health

How seven Performance Beef customers are harnessing cattle management technology to track animal health, get data-driven insights and better manage herd health.

Steve and Riley Van Heerde

Estelline, South Dakota

Steve Van Heerde and his teenage son, Riley, share a passion for the cattle industry that has grown into an 800-head feedlot. The duo uses technology to save time and build a profitable, thriving business.

Comparing low-frequency and ultra-high-frequency EID tags for cattle

What's the difference between low-frequency (LF) and ultra-high frequency (UHF) EID tags?